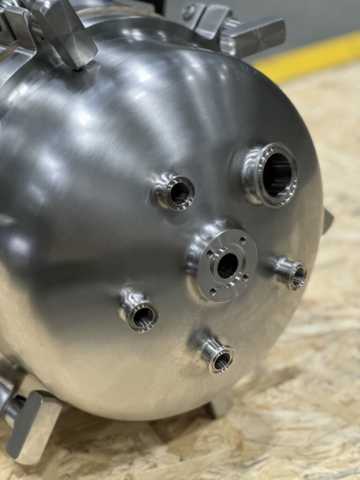

PRESSURE VESSEL GFD 500

In November, we completed the production of the GFD 500 pressure vessel made from a special nickel alloy, Hastelloy C22. This material provides excellent corrosion resistance and is ideal for environments with high concentrations of aggressive acids where standard stainless steel materials are not suitable. The vessel is designed for pharmaceutical processes, especially the preparation, mixing and drying of active pharmaceutical ingredients (API). It is a key component of the Nutsche Filter type pressure filter dryer, which combines filtration and drying in one unit.

It is a miniature version of a commercial filter dryer that enables efficient filtration and drying with the same reliability and benefits as large filter dryers. Designed to overcome the well-known production challenges manufacturers face when using traditional production methods such as Büchner filtration and drying samples in a bowl dryer, it is the ideal technology for successfully completing up-scaling and down-scaling of particles, respectively, and for obtaining predictive performance results.

The apparatus consists of a stirred vessel designed to operate under vacuum and pressure. The vessel has a heated jacket for efficient drying. Separation of solids and liquids is accomplished in a unique filter basket that can be removed to facilitate and maximize product collection. The filter dryer is designed for research institutes, laboratories, universities and companies in a wide range of industries. This technology helps scientists and process engineers innovate and optimize their unique processes worldwide.